The Evolution of Screen Printing: From Traditional to Modern Techniques

The Evolution of Screen Printing: From Traditional to Modern Techniques

Screen printing, also known as serigraphy, has a rich and varied history that stretches back over a thousand years. This versatile printing method has evolved significantly, transitioning from traditional manual processes to advanced modern techniques. The journey of screen printing reflects the industry's adaptability and innovation, influenced by changes in technology, materials, and artistic approaches. In this post, we’ll explore the fascinating evolution of screen printing, from its ancient origins to the high-tech applications we see today.

Early Beginnings: The Roots of Screen Printing

The earliest forms of screen printing can be traced back to ancient China during the Song Dynasty (960–1279 AD). Artisans used silk screens and stencils to transfer intricate designs onto fabric. This technique eventually spread to other parts of Asia, including Japan, where it became an integral part of textile art.

In the late 18th century, screen printing made its way to Western Europe. Initially used for industrial applications, the method became popular for printing wallpaper and fabric patterns. The introduction of silk mesh and other synthetic materials allowed for greater detail and consistency in prints.

The 20th Century: The Rise of Commercial Screen Printing

The 20th century marked a significant turning point for screen printing, as it began to be widely used in commercial and artistic contexts. In the 1930s, artists like Andy Warhol popularized screen printing as an art form, known as Pop Art. This period saw the development of photo-emulsion techniques, which revolutionized the process by allowing for more complex and detailed images.

During the 1960s and 1970s, screen printing became a mainstream method for producing posters, t-shirts, and promotional materials. The introduction of plastisol inks further expanded the medium's possibilities, enabling vibrant, long-lasting prints on various substrates.

Modern Advancements: Digital and Automated Techniques

Today, screen printing has embraced digital advancements, making the process more efficient and versatile. Automatic screen printing machines have significantly increased production speed and consistency, making it easier to produce large volumes of high-quality prints. Digital screen printing technology, such as Direct-to-Screen (DTS) systems, has streamlined the pre-press process, reducing the need for physical screens and stencils.

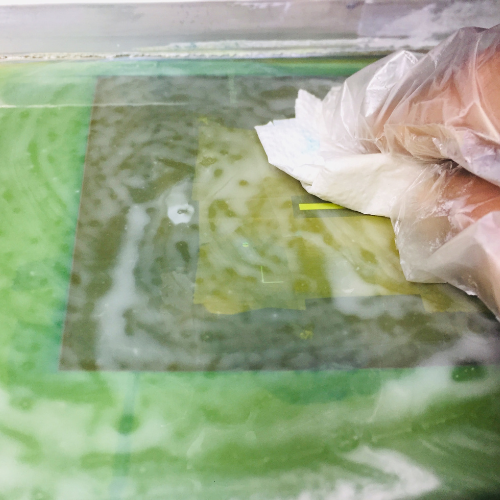

The evolution of inks and substrates has also played a crucial role in modern screen printing. Eco-friendly water-based inks and specialty inks, such as metallic and glow-in-the-dark, have broadened the creative possibilities. Additionally, advancements in mesh technology and emulsion chemistry have improved the durability and precision of screens.

The Future of Screen Printing

As technology continues to advance, the future of screen printing looks promising. Innovations in automation, digital integration, and sustainable practices are set to further transform the industry. The increasing demand for custom and personalized products also opens up new opportunities for screen printers to explore niche markets and innovative applications.

Screen printing has come a long way from its humble beginnings, evolving into a sophisticated and versatile method for creating vibrant, detailed prints. At Sias Canada Inc., we are proud to offer a wide range of screen printing equipment and supplies, from traditional to cutting-edge technologies. Contact us to learn more about how we can support your screen printing journey.